Gooseneck Press Brake Tools: Versatile Solutions for Precision Bending

Deep channel bending and metal box forming solutions for GCC metalworking industries

When it comes to creating metal boxes and achieving deep U-channel bending, gooseneck press brake tools are the perfect choice. These specialized tools, including gooseneck dies and punches, allow you to shape channels and U-profiles with ease and precision.

Gooseneck Dies

Gooseneck dies are specifically designed to overcome the limitations of straight-sided dies when creating channels or special shapes. With a deeper "throat" extending beyond the die centerline, they enable a wider return flange while reducing die capacity. This unique design provides flexibility and versatility in achieving complex bends.

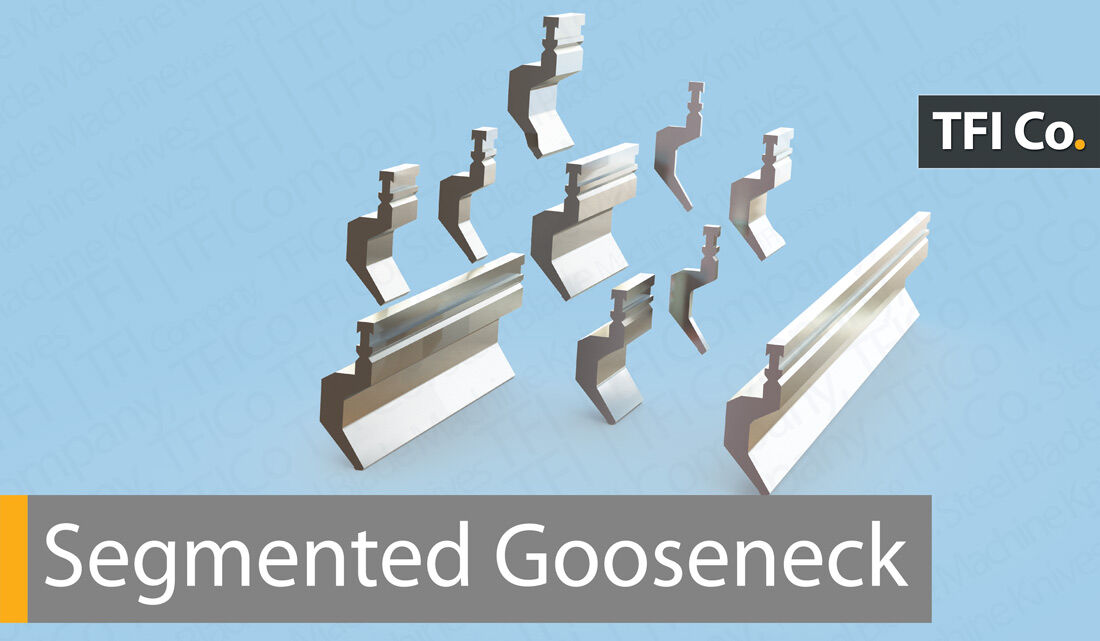

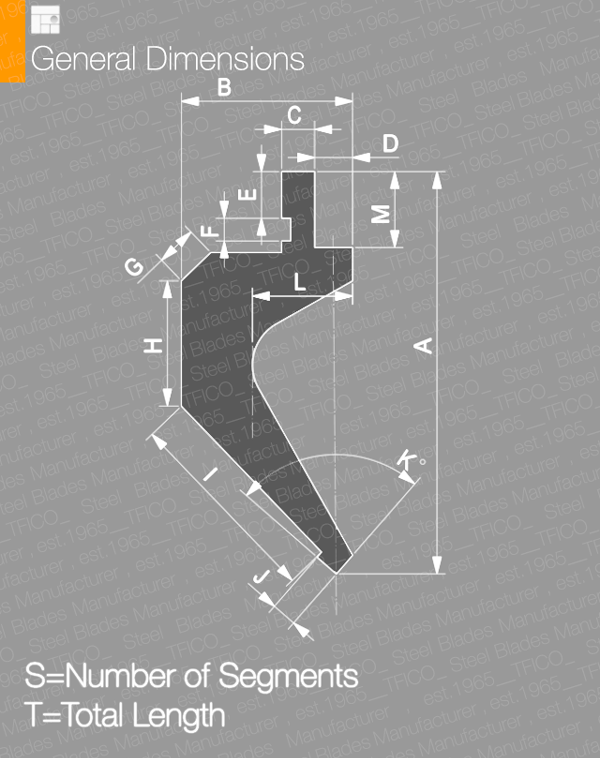

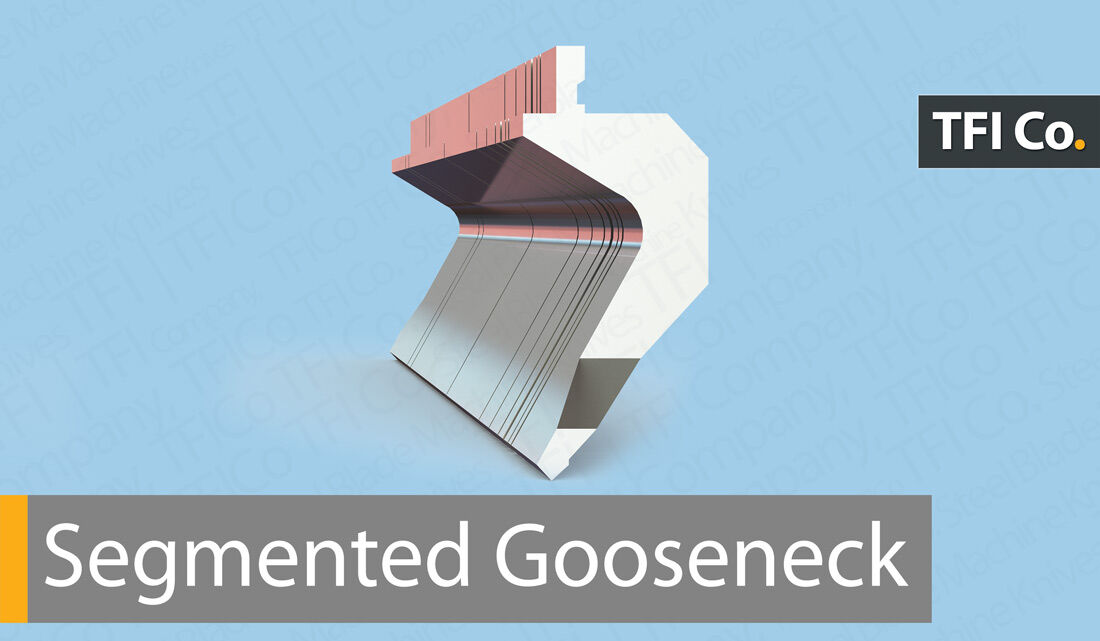

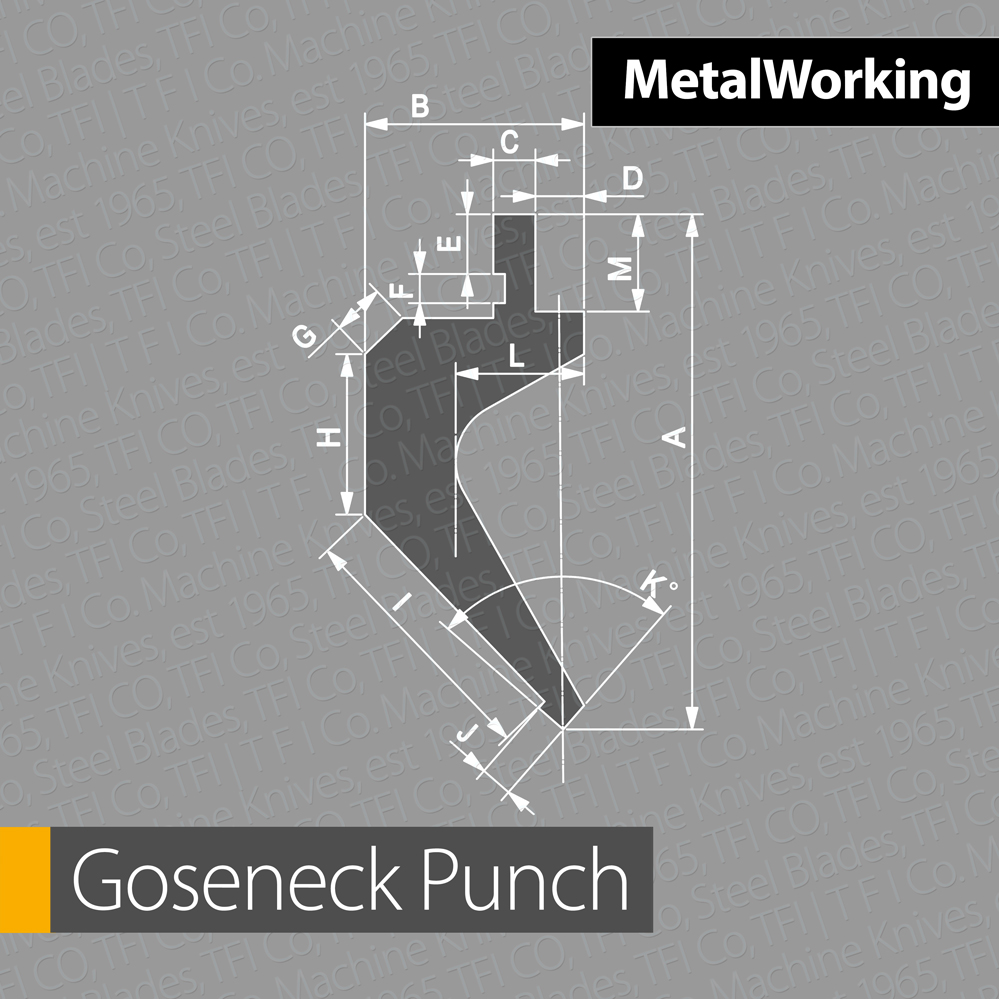

Gooseneck Punches

Gooseneck punches, on the other hand, are ideal for bending channels and U-profiles. These punches feature a body that extends towards the front of the press brake, with a large concave area facing the inside. This design allows for the bending of larger flanges into the space where a standard punch would typically be positioned. While gooseneck punches offer great utility for U-profiles, it's important to understand their limitations.

Important Technical Specifications

It's essential to note that gooseneck punches have a maximum capacity and are not as strong as standard punches. While they are sturdy and reliable, their force line is not fully supported as it reaches the workpiece. However, within their design limitations, gooseneck punches provide excellent results for a wide range of bending applications.

TFI Co. manufactures specialized gooseneck press brake tools for deep channel bending, metal box forming, and U-profile applications. Our gooseneck dies and punches provide the flexibility and precision needed for complex metalworking projects across UAE, Saudi Arabia, Qatar, Oman, and Kuwait.