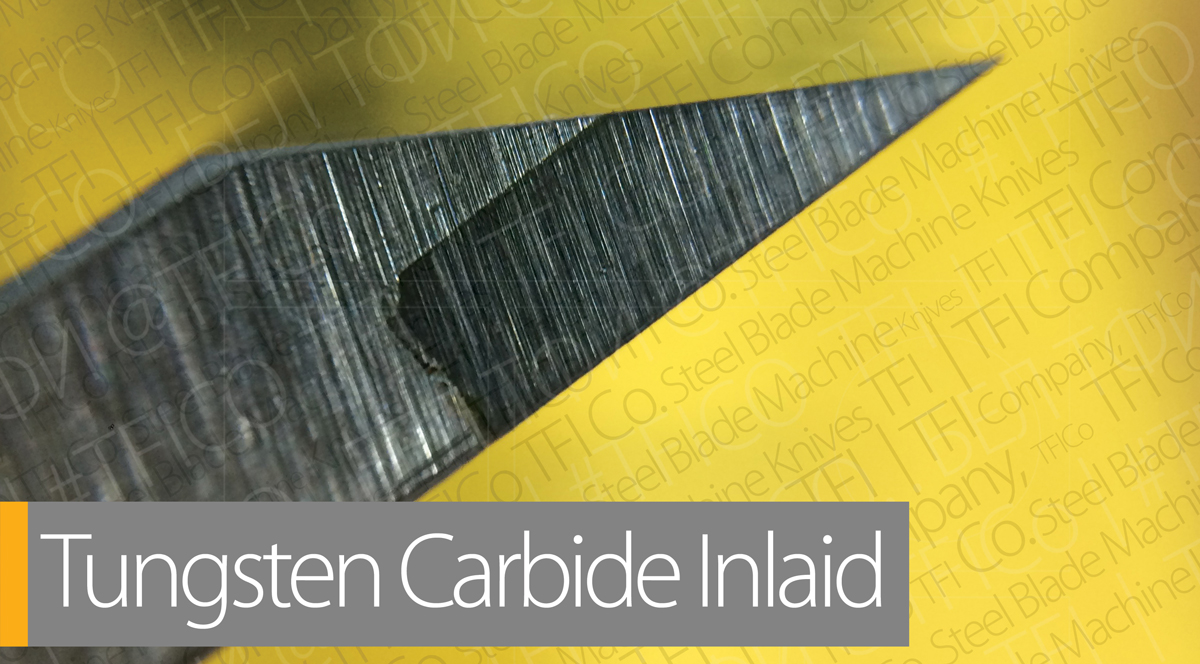

Tungsten Carbide Inlaid

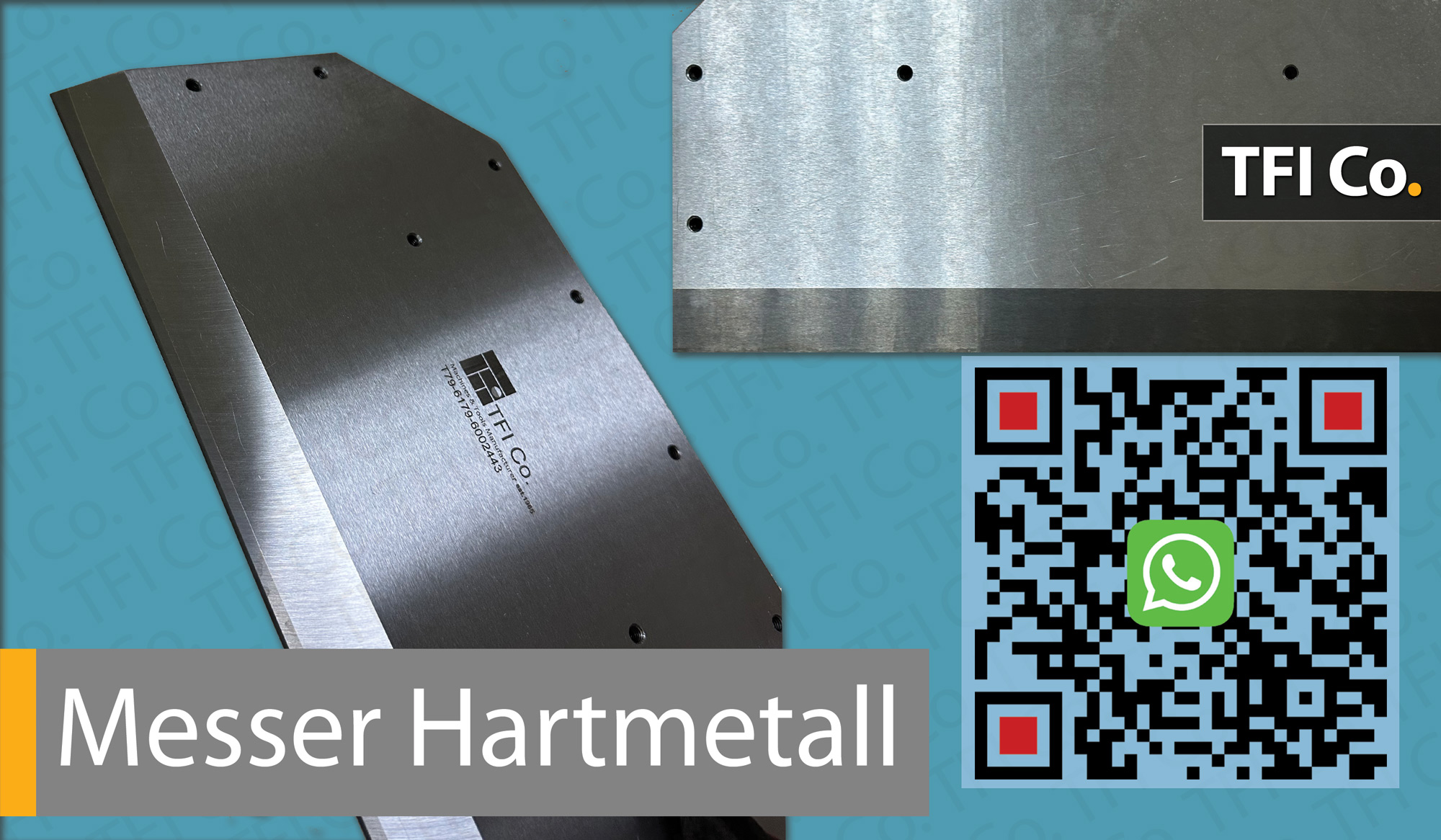

Tungsten Carbide Machine Knives in Saudi Arabia Qatar United Arab Emirates Oman Kuwait Bahrain For Paper Industry Manufactured By TFICo. Steel Blades and machine Knives manufacturer est. 1965

We are always there for you to received your order

Please Call us and let us know your machine model

Precision and Durability: TFI Co. Industrial Knife

For over two decades, TFI Co. Industrial Knife has been at the forefront of manufacturing the finest inlaid tungsten carbide machine knives and scraper blades in the world. Our unwavering commitment to quality is evident in our exclusive "tungsten carbide to metal" bonding process, ensuring exceptional edge performance and remarkable shock toughness.

With our precision grinding process, we achieve a seamless transition from the robust backing material to the resilient carbide inlay. This seamless integration enhances the overall performance and durability of our blades, allowing them to withstand the most demanding industrial applications with ease.

Unique Blade Design

Our blades consist of two essential parts that work in perfect harmony to deliver exceptional results:

- Brazed Tungsten Carbide Insert: The high-density tungsten carbide insert provides unparalleled hardness and wear resistance, ensuring long-lasting cutting performance even in the harshest environments.

- Normal Steel or Soft Steel Body: The sturdy steel body provides the necessary strength and stability, allowing the blade to withstand heavy-duty use and maintain its precision over time.

Tungsten Carbide Blades - Precision Surface Grinding

Experience the highest level of precision and quality with Tungsten Carbide Blades from TFI Co. Our blades are expertly surface ground to perfection, leveraging decades of experience in the industry. With our cutting-edge grinding techniques, we ensure unparalleled precision and consistency.

Cut-to-Length Transformer Machine Blades - Unrivaled Manufacturing Excellence

TFI Co. is your trusted manufacturer of Cut-to-Length Transformer Machine Blades. Our blades are specifically designed for shearing silicon steel sheets in cut-to-length lines. With our advanced TCT (Tungsten Carbide Tipped) inlay shear blades, you can expect exceptional precision and high abrasion resistance. Experience the difference in performance and reliability.

Blades for Cut-to-Length Lines - Industry-leading Brands

At TFI Co., we proudly manufacture blades for various cut-to-length lines, including MAXIMA, POLAR, ITOH, GEORG, Novaslits, Bu-tech Bliss, Fimi, CAMU, SMS SIEMAG, Nobag, and more. Our blades are crafted with utmost precision and durability to meet the demanding requirements of the industry. Count on us for superior quality and performance.

Customized Knives for Transformer Companies - Unmatched Precision

Transform your cutting processes with our customized knives tailored for transformer companies. We understand the critical importance of precise silicon sheet cutting in the transformer industry. Our knives deliver exceptional cut-to-length preciseness, ensuring optimal results and efficiency. Trust TFI Co. for your cutting needs in UAE, Qatar, Oman, Saudi Arabia, and beyond.

Upload Your Drawings Now Call us now Video instructionsManufacturing Process for Inlay Tungsten Carbide Knives

At TFI Co., we utilize advanced manufacturing techniques to create Atlas knives renowned for their quality. Our skilled craftsmen carefully choose high-grade tool steel as the base material for these knives. Employing modern machinery and precision methods, we shape the blades into various configurations suitable for diverse cutting tasks in the printing industry.

Tungsten Carbide Inlay Knives

To enhance cutting performance and durability, we incorporate tungsten carbide inlay onto the cutting edges of our Atlas knives. Through meticulous bonding techniques like brazing or laser welding, the tungsten carbide seamlessly integrates with the blade, offering exceptional hardness and resistance to wear. This ensures that our knives remain sharp even when cutting abrasive materials, resulting in extended blade life and reduced downtime.

Customization

Recognizing that each printing application has unique demands, we provide customization services to tailor Atlas knives to your specific requirements. Whether you need straight blades, circular blades, or custom shapes, our team collaborates with you to deliver knives precisely aligned with your cutting needs.

Re-Sharpening Services

Besides manufacturing, TFI Co. offers professional re-sharpening services to ensure peak performance of your Atlas knives over their lifespan. Our skilled technicians employ precise grinding techniques to restore the cutting edges of dulled blades, effectively rejuvenating their cutting abilities. By entrusting your knives to us for re-sharpening, you can prolong their lifespan and minimize downtime, ultimately enhancing your operational efficiency.

GCC Market - UAE - Saudi Arabia - Oman - Qatar

TFI Co. takes pride in serving the dynamic markets of Dubai and Abu Dhabi, addressing the diverse needs of the printing industry in the UAE. Whether you operate a printing press, packaging facility, or specialize in printing services, our precision Atlas™ knives and re-sharpening solutions are tailored to elevate your cutting processes, ensuring efficiency and quality.

Fill out form Call us now Video instructions