Gooseneck Punch

Choosing the Perfect Gooseneck: Precision Tailored to Your Needs

When it comes to selecting the ideal gooseneck press brake tool, several essential factors should be taken into consideration. By carefully assessing these factors, you can ensure that the chosen tool aligns perfectly with your bending requirements, material characteristics, machine compatibility, and overall application needs.

Determining Your Bending Requirements

Start by clearly defining the specific bending operations and the level of complexity you aim to achieve. Evaluate the shapes and forms you need to create, and consider how the curve radius and shape of the gooseneck tool can complement and optimize your bending processes.

Material Thickness and Type Considerations

Different materials possess distinct properties, and their thicknesses can vary significantly. It's crucial to select gooseneck tooling that caters to the unique characteristics of your chosen material. Take into account factors such as tensile strength, elasticity, and other material-specific requirements to ensure superior bending results.

Ensuring Machine Compatibility

To achieve seamless integration and exceptional performance, it's essential to verify the compatibility of the gooseneck tooling with your specific press brake machine. Carefully review the tooling specifications and compare them with your machine's capabilities and tooling requirements. This step guarantees optimal functioning and exceptional results.

Leveraging Application Expertise

When in doubt or seeking professional guidance, turn to the expertise of tooling specialists and manufacturers. Their deep understanding of press brake applications and industry nuances enables them to offer invaluable insights and recommendations. By analyzing your bending needs, material requirements, and machine capabilities, they can provide you with expert advice and guide you towards the most suitable gooseneck press brake tool.

Countries We Proudly Serve

We take immense pride in having served numerous industries in the following countries, and we eagerly look forward to expanding our services to more countries in other regions:

- United States

- United Kingdom

- Germany

- France

- Italy

- Spain

- Canada

- Australia

- Japan

- Saudi Arbia

- UAE (Dubai, Abudhabi , Sharjah, Ras Al Khaima

- Oman

- Kuwait

- Belarus

Gooseneck Press Brake Tools: Enhancing Precision and Versatility

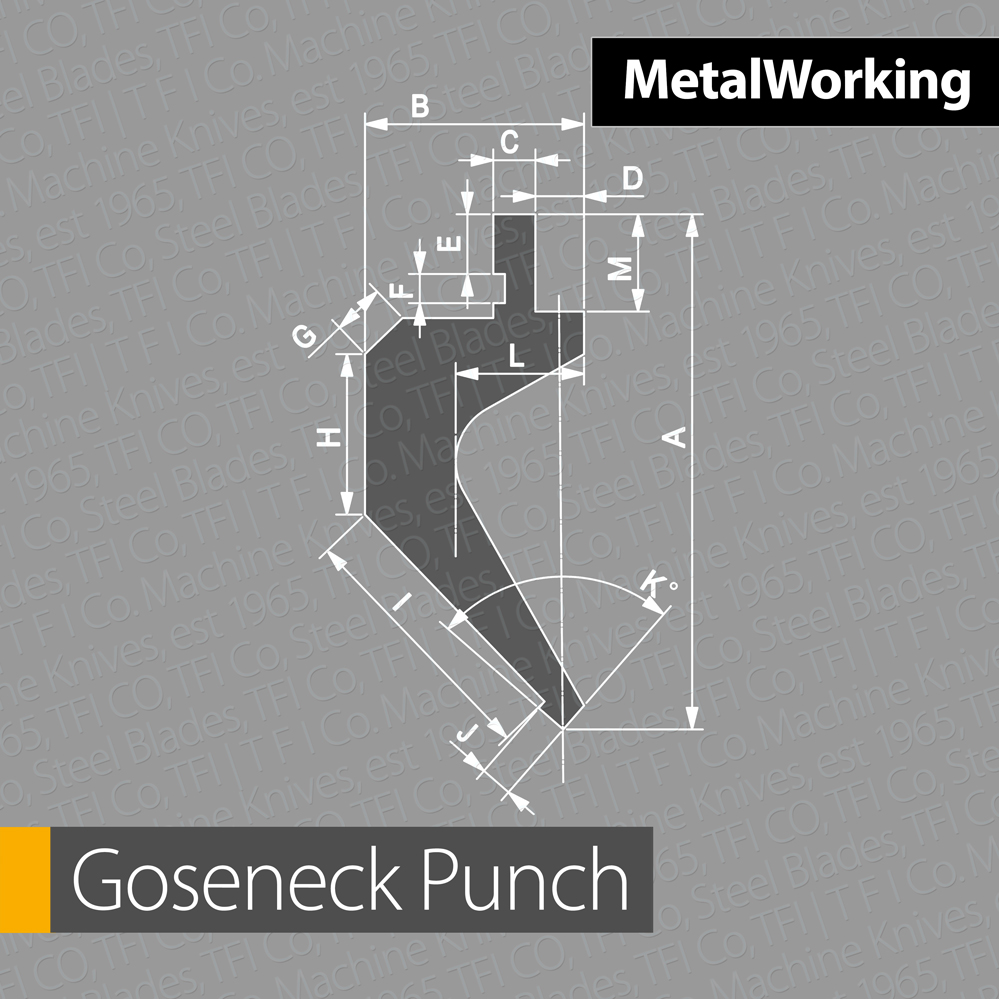

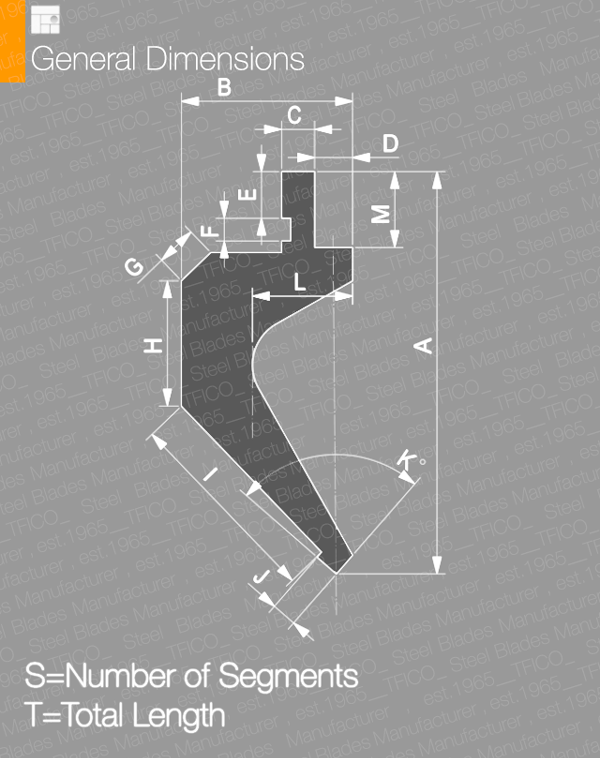

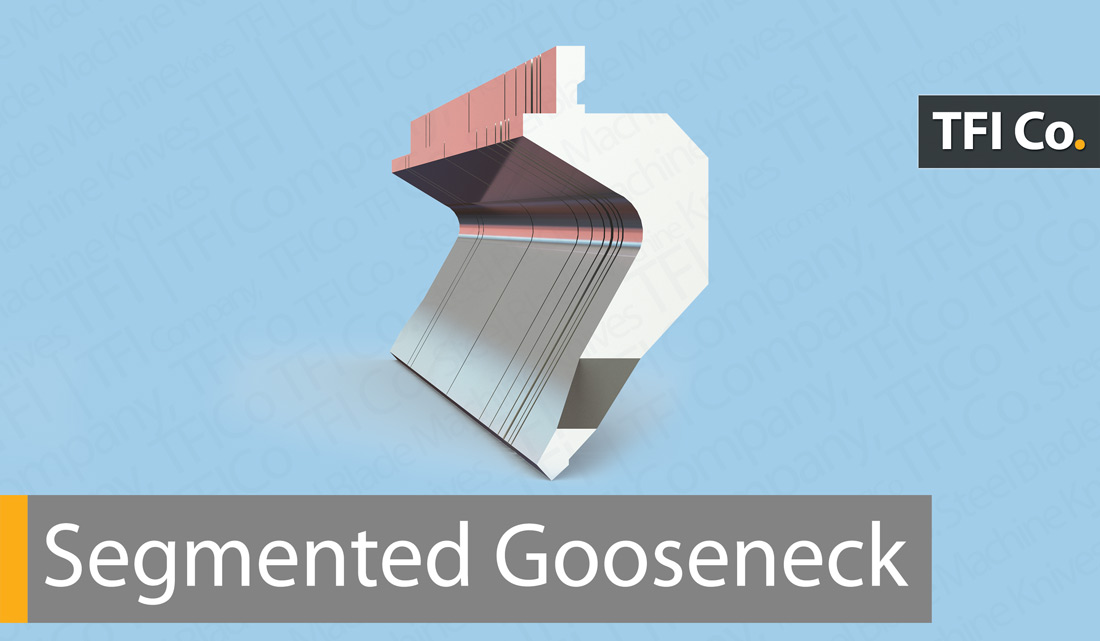

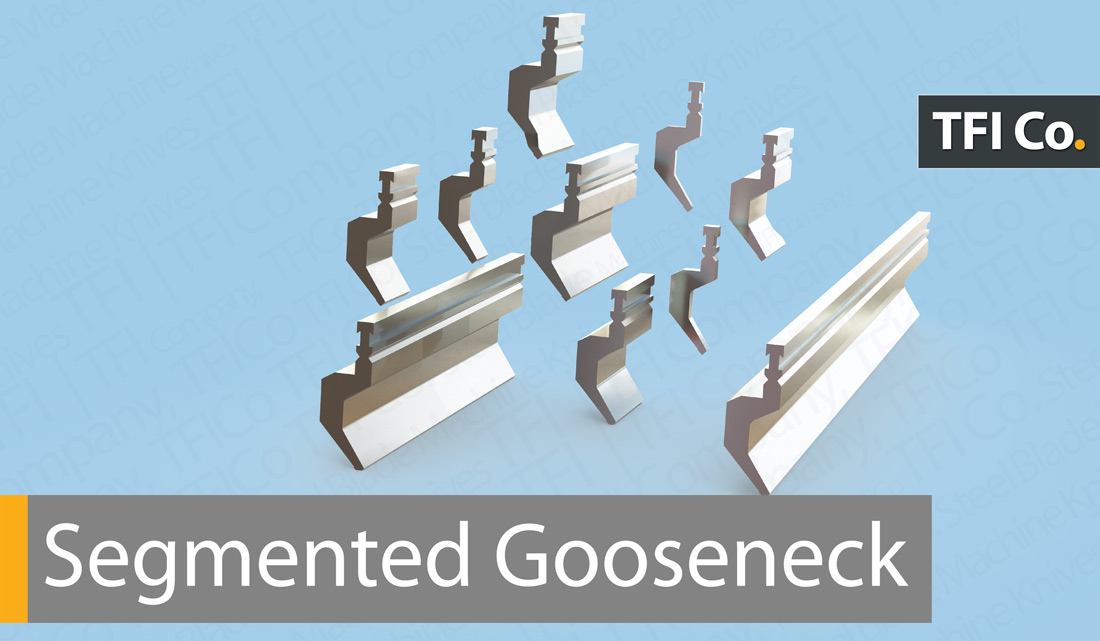

Gooseneck press brake tools, also referred to as gooseneck punches and male molds, are expertly crafted tooling components that revolutionize sheet metal bending in press brake machines. With their distinctive curved or gooseneck shape, these tools unlock a whole new level of flexibility and versatility in bending operations.

Advantages of Gooseneck Press Brake Tools

- Improved Accessibility: The gooseneck design provides unparalleled access to the workpiece, even when bending deep or complex shapes. It empowers operators to effortlessly reach areas that would otherwise pose challenges with standard tooling.

- Minimized Material Distortion: By harnessing the power of the gooseneck shape, these tools excel at minimizing material distortion during the bending process. They ensure a more uniform distribution of the bending force, resulting in remarkably smooth and precise bends.

- Expanded Bending Options: Gooseneck tools open up a world of possibilities in bending operations. They enable a wider range of bending options, including the ability to bend flanges close to existing bends, create elegantly curved edges, and fabricate intricate shapes that necessitate a combination of straight and curved bends.

Countries We Have Proudly Served

We take immense pride in having served numerous industries in the following countries, and we eagerly look forward to expanding our services to more countries in other regions:

- United States

- United Kingdom

- Germany

- France

- Italy

- United Arab Emirates

- Canada

- Australia

- Japan

Gooseneck Press Brake Tools: Versatile Solutions for Precision Bending

When it comes to creating metal boxes and achieving deep U-channel bending, gooseneck press brake tools are the perfect choice. These specialized tools, including gooseneck dies and punches, allow you to shape channels and U-profiles with ease and precision.

Gooseneck dies are specifically designed to overcome the limitations of straight-sided dies when creating channels or special shapes. With a deeper "throat" extending beyond the die centerline, they enable a wider return flange while reducing die capacity. This unique design provides flexibility and versatility in achieving complex bends.

Gooseneck punches, on the other hand, are ideal for bending channels and U-profiles. These punches feature a body that extends towards the front of the press brake, with a large concave area facing the inside. This design allows for the bending of larger flanges into the space where a standard punch would typically be positioned. While gooseneck punches offer great utility for U-profiles, it's important to understand their limitations.

It's essential to note that gooseneck punches have a maximum capacity and are not as strong as standard punches. While they are sturdy and reliable, their force line is not fully supported as it reaches the workpiece. However, within their design limitations, gooseneck punches provide excellent results for a wide range of bending applications.