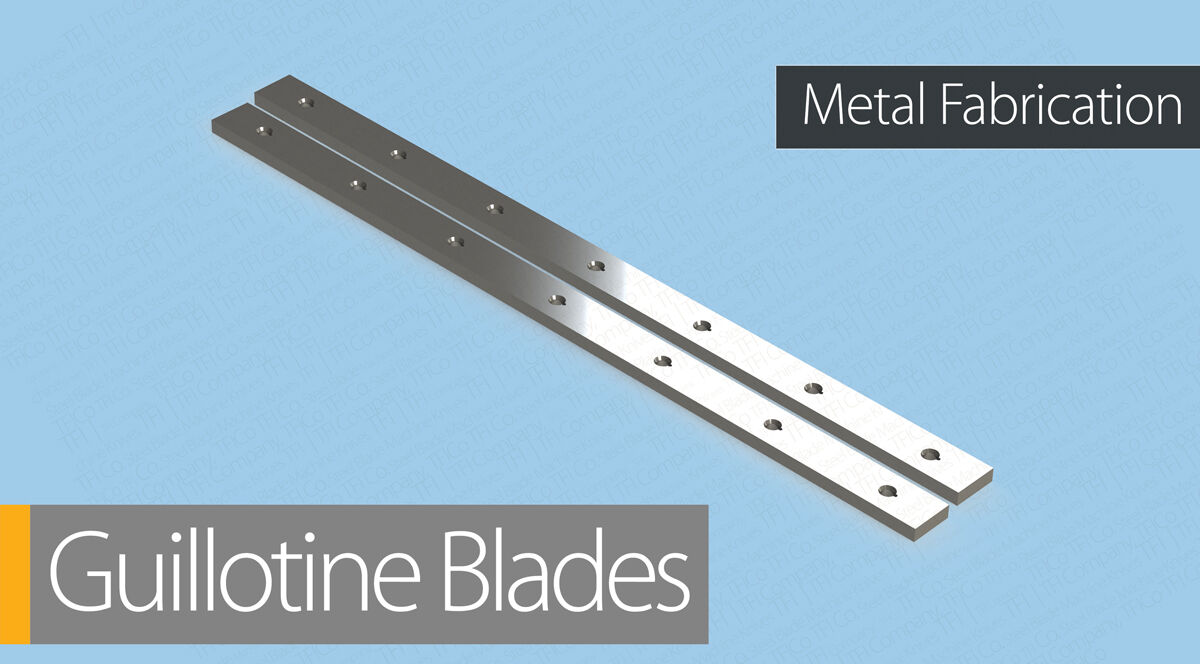

Guillotine Shear Blades

Guillotine shear blades are one of the most crucial components of metalworking machines. At TFI Co., we manufacture high-quality guillotine shear blades for metalworking industries, designed to withstand heavy loads and deliver precise and smooth cutting. Our blades are made with the finest raw materials and are engineered to provide a long-lasting and reliable cutting performance.

Notching Shear Blades

At TFI Co., we manufacture high-quality notching shear blades for metalworking industries. Our notching shear blades are designed to withstand high cutting forces and deliver a precise and clean cut. We use only the finest raw materials to manufacture our blades, and our team of experts ensures that each blade meets the highest quality standards.

Metalworking Sandwich Panel Shear Blades

Sandwich panel shear blades are a critical component in the metalworking industry, designed to cut through the sandwich panels with precision and accuracy. At TFI Co., we manufacture high-quality sandwich panel shear blades designed to deliver a precise and clean cut. Our sandwich panel shear blades are made with the finest raw materials, and our team of experts ensures that each blade meets the highest quality standards.

Rebar Shear Blades

Rebar shear blades are a critical component in the reinforcement bar cutting process. At TFI Co., we manufacture high-quality rebar shear blades designed to withstand heavy loads and deliver precise and accurate cuts. Our rebar shear blades are made with the finest raw materials and are designed to deliver a long-lasting and reliable cutting performance.

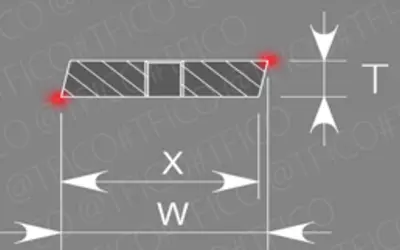

Swing Beam Shear Blades

Swing beam shear blades are one of the most crucial components of shearing machines, designed to deliver a precise and smooth cut. At TFI Co., we manufacture high-quality swing beam shear blades designed to withstand heavy loads and deliver a long-lasting and reliable cutting performance. Our swing beam shear blades are made with the finest raw materials, and our team of experts ensures that each blade meets the highest quality standards.

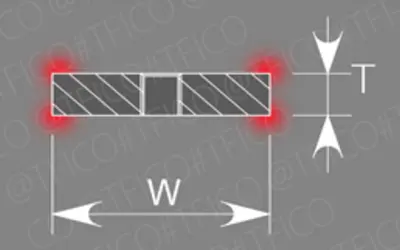

Corner/Angle Cutting Shear Blades

Corner and angle cutting shear blades are a critical component in multi-functional ironworker machines, designed to deliver precise and accurate cuts. At TFI Co., we manufacture high-quality corner and angle cutting shear blades, designed to withstand heavy loads and deliver a long-lasting and reliable cutting performance. Our corner and angle cutting shear blades are made with the finest raw materials, and our team of experts ensures that each blade meets the highest quality standards.

Countries We Already Served

We proudly serve the industries in the following countries and look forward to serving more countries in other regions too:

- Saudi Arabia

- UAE

- Qatar

- Oman

- Belarus

- Russia